Green Lumber

by Nick Gromicko, Rob London and Kenton Shepard

"Green lumber" is another term for wet lumber, which is wood used in construction that has a moisture content of more than 19%. Moisture Content

Green lumber is more commonly used in arid regions of the United States, such as Arizona and parts of California, because the wood will dry more quickly. Damper regions often require kiln-dried wood, which must have a moisture content of 19% or less. The additional expense of kiln-dried wood is the reason it is used in only a small portion of construction.

Freshly cut wood will gradually lose moisture until it reaches equilibrium with its surroundings, which is referred to as its "equilibrium moisture content" (EMC). As it  dries, the wood will shrink in size. Wood will continue to lose moisture until it reaches EMC, at which point it's said to have reached its "in-service condition."

dries, the wood will shrink in size. Wood will continue to lose moisture until it reaches EMC, at which point it's said to have reached its "in-service condition."

The water that fills wood cells is known as "free water," which accounts for most of the water weight of a tree. Cell walls also contain water, which is known as "bound water." The weight of the water can account for more than half the mass of a tree in some species when it is cut down. Ideally, the lapse between the time the tree is first cut until the tree's wood is used in construction will allow for most or all of the free water to evaporate, but this does not always happen. Shortly after wood is processed in mills, it is bundled and wrapped in plastic, which retards evaporation. The wood has little chance to dry until the bundle is unwrapped and the framing process begins at the construction site.

Why is green lumber used?

- It is relatively inexpensive.

- Green lumber is softer than seasoned wood. It can be cut more easily, is not as likely to split, and nails can be driven into it more easily.

Problems associated with the use of green lumber:

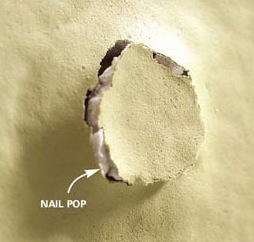

- nail pops. Where wood frame members shrink, a gap is created between the nail and the drywall. If the drywall and nail are pushed together, the nail may force the drywall surface to elevate. A common place for nail pops to occur is at the base of vaulted ceilings near external walls. Although unsightly, they usually do not affect the building's structural integrity. Homeowners who wish to fix this problem can simply push the nail further into the wall;

- mold. Mold can begin to grow on green lumber before it is even used in construction. Airborne mold spores are found almost everywhere, and they can easily cause mold growth on wet wood surfaces, especially while it is being transported long distances by train;

- difficult to paint or stain. Low-permeability paint can prevent water vapor from exiting the wood, resulting in bubbling of the painted surface;

- sap. Sap and other liquid substances within the wood's interior can ooze out and cause discoloration.

- gaps in exterior trim can be created during shrinkage. This is especially true at the fascia.

In summary, a number of problems can result from the use of green lumber. Wood decay

For the best inspector in your neighborhood, visit: www.InspectorSEEK.com More inspection articles like this.

Comments(6)